From PCB design to full-scale product manufacturing under one roof.

From concept to commissioning, we deliver turnkey engineering projects across industry facilities, infrastructure, and building systems.

Backed by decades of global experience in design and production.

Serving Consumer Electronics, Automotive, Healthcare, and Defence sectors.

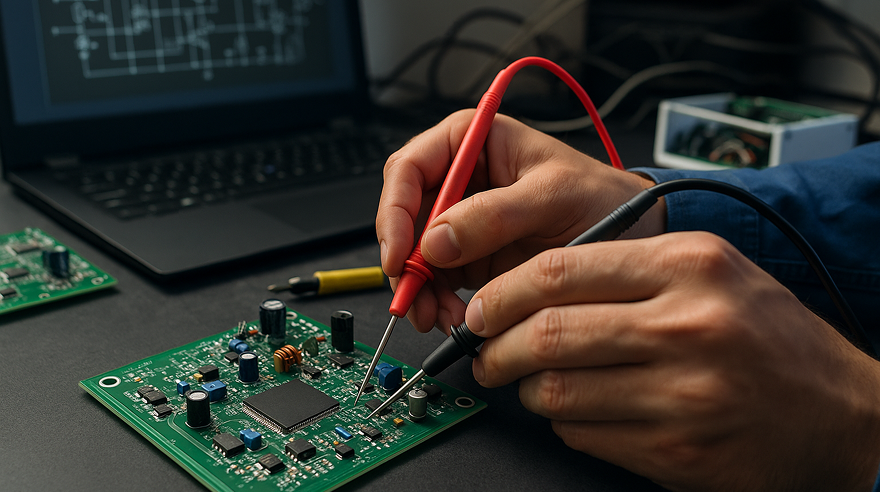

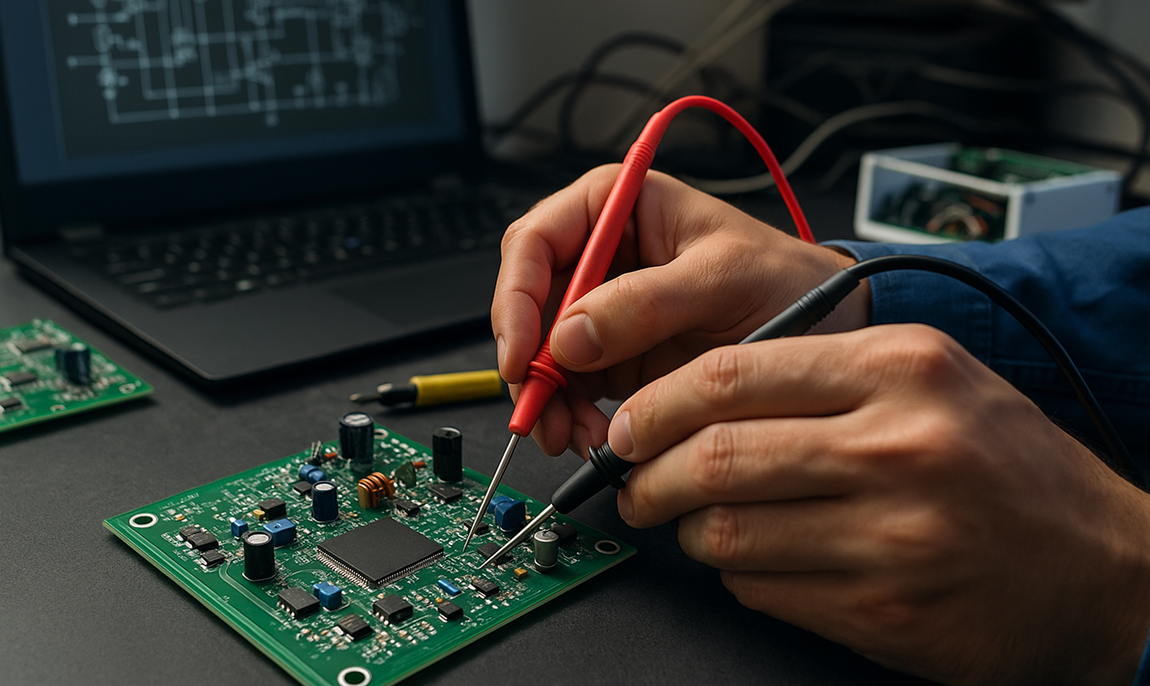

We transform product ideas into intelligent,

manufacturable electronic designs through advanced R&D, prototyping, and engineering.

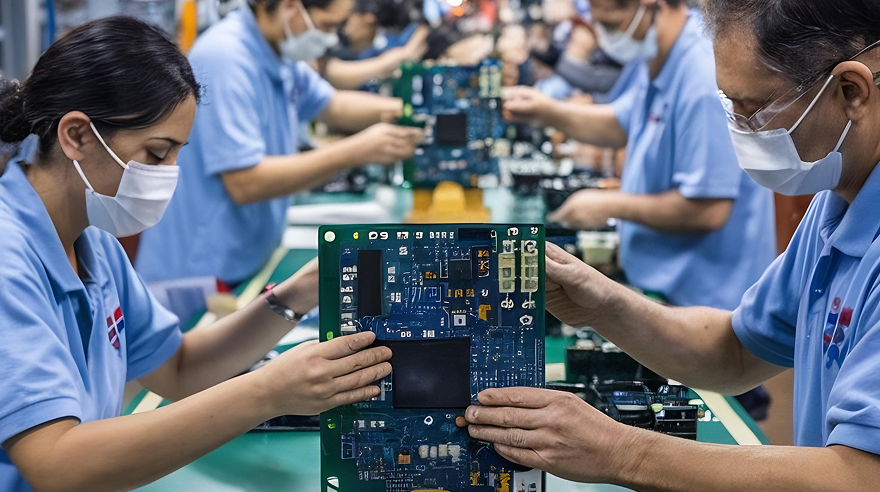

We deliver precision, scalability, and quality through

automated PCB assembly, system integration, and end-to-end production.

We provide complete turnkey solutions — from design and manufacturing to branded, market-ready electronic products.

We power diverse industries — from consumer electronics to automotive, healthcare, and defense — through innovation, precision, and reliability, delivering world-class design and manufacturing excellence that helps global brands build smarter, more efficient, and future-ready electronic systems.

Interactive, durable kiosks for retail, banking, and public services.

Secure, seamless biometric authentication systems.

Reliable contactless solutions for logistics, payments, and ID

High resolution commercial display systems for smart communications.

Real time MES visibility and operational efficiency.

PCBA Units / Year

Set Top Boxes / Year

Indoor Display Units / Year

We deliver world-class Electronics Manufacturing Services with precision, scalability, and reliability. From automated PCB assembly and system integration to testing, sourcing, and compliance, we ensure defect-free builds and on-time delivery. Our ISO- and RoHS-compliant facility combines advanced automation, sustainable operations, and global sourcing excellence to power next-generation electronic products.

₹1000+ Cr Turnover

100+ years of combined global expertise in design, operations, and scale.

Fully automated SMT lines with certified ISO/ RoHS quality systems.

Customizable capacity and infrastructure to match your growth roadmap.

Seamless design-to-manufacturing workflow ensuring faster delivery.

Financially strong, technologically agile, and globally recognized partner.

OEM (Original Equipment Manufacturer) means EmpradaTEK manufactures products based on your design and specifications, branded under your name.

ODM (Original Design Manufacturer) means EmpradaTEK designs and manufactures innovative products that you can rebrand and sell under your label.

EmpradaTEK offers OEM & ODM services for electronics, IoT devices, smart automation systems, industrial controllers, power solutions, and embedded systems. We also customize hardware and software based on client requirements.

MOQ depends on the product type and customization level. For most projects, EmpradaTEK maintains flexible MOQs to support startups and mid-sized brands.

Our process includes:

Requirement Discussion – Understanding client needs and specifications.

Concept Design & Prototyping – Creating design mockups and functional prototypes.

Testing & Validation – Ensuring quality and performance standards.

Mass Production – Scalable manufacturing with quality control.

Branding & Packaging – Custom labeling and packaging for your brand.

Yes, EmpradaTEK specializes in customized hardware and firmware. You can modify features, design, housing, or software according to your project’s requirements.

Every product undergoes strict quality control at each stage — from design validation, PCB testing, and firmware debugging to final inspection. Our facilities follow international quality and safety standards.

Yes. We understand the importance of IP protection and sign NDAs (Non-Disclosure Agreements) with all OEM/ODM clients to safeguard your product ideas and designs.

Lead times vary by complexity — typically 4–8 weeks for design and prototyping, and 6–10 weeks for mass production after design approval.

Yes. We help clients obtain required product certifications (CE, RoHS, FCC, BIS, etc.) to ensure market readiness.

We offer technical support, firmware updates, spare part supply, and warranty service to ensure long-term performance and customer satisfaction.